-

+86-371-86159555

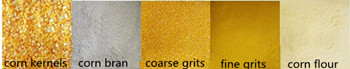

Corn grits milling machine can also finish the process of corn peeling and degermination. Due to the easy structure, low power consumption and high peeling and degermination efficiency, corn grits milling machine is quite popular.

CORN GRITS MILLING MACHINE working principle and the main structure is similar with horizontal type of wheat scourer. The difference is the surface condition of the riddle drum. The riddle drum consists of two sections. The feeding part is scale shape screen, which can help corn friction and peeling. The discharging part is punching screen which can make the smashed small granules discharge out of the screen drum.

The corn enters into the machine. The rotating plate strikes and blends with high speed, and hits and rubs the screen drum inner wall. Under this effect, corn is peeled and then corn germs are separated from the albumen. Corn husk, grits and germs are discharged under the plate propelling from exit. The pressure door which adjusts the discharging mechanism controls peeling and degermination efficiency. Flour, small broken granules and germs are discharged from the screen underflow exit though the sieve pore.

+86-371-86159555

86635803

No. 57 Science Avenue

Zhengzhou, Henan, China

7*24 hours

Human services